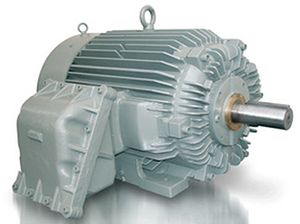

Explosion-proof motors are designed to prevent the ignition of flammable gases or vapors in hazardous environments. They are constructed with robust materials and features to contain potential explosions within the motor enclosure. These components are often used in the oil and gas, chemical, and mining industries, where the presence of volatile substances poses a risk.

At Dietz Electric Co., we offer Class I, Division 1 motors that undergo thorough testing and scrutiny to ensure they meet the highest safety standards. Our quality dedication extends to standard and custom electric motors, catering to diverse industrial requirements. We also have certifications from the Underwriters’ Laboratories Inc. (UL), the National Electrical Manufacturers’ Association (NEMA), and the Canadian Standards Association (CSA).

What Is a Class I, Division 1 Motor?

A Class I, Division 1 motor is designed to operate safely in environments with significant risk of explosions. This ensures that potential ignition is contained within the motor’s housing. Its classification system is determined by UL and the Canadian Electrical Code (CE). This is crucial in selecting the appropriate motor for a given operating environment.

The Class I designation refers to environments containing combustible atmospheric gases or vapors that pose a risk of explosion or ignition. Meanwhile, Division 1 specifies that explosive or ignitable materials commonly exist under normal working conditions. This emphasizes the frequency of combustible substances in the atmosphere. Additionally, Class I environments are further classified into groups (A through D) based on the auto ignition temperature of the gasses or dusts.

Class I, Division 1 motors must meet specific criteria to be classified as explosion-proof. First, they must be designed to contain internal explosions, with long, narrow flame paths that cool gases heated during ignition. While they do not prevent explosions, they must confine them within the housing, preventing the ignition of the surrounding environment. The construction of these motors must also be robust enough to withstand explosions, with longer flame paths and tighter tolerances.

Best Applications of Class I, Division 1 Motors

The following are the industries and facilities that often incorporate Class I, Division 1 motors into their operations:

Petroleum Refining Plants

The production and processing of crude oil in petroleum refining plants involves handling highly volatile and combustible chemicals. Class I, Division 1 motors are essential in these settings for powering machinery such as pumps and compressors.

Utility Gas Plants

Utility gas plants deal with the processing and distribution of natural gas, which can be combustible. The motors power various equipment in these facilities, ensuring that they operate safely in environments with explosive materials.

Spray Painting Areas

Environments where spray painting occurs often have high concentrations of volatile solvents and paint fumes. Class I, Division 1 motors are used to power equipment like exhaust fans and ventilation systems in these areas.

Aircraft Hangars

Aircraft hangars contain aircraft, fuel, and other flammable materials, creating a potentially hazardous environment. The motors are employed to power equipment such as ventilation systems and fuel transfer pumps. Their ability to contain internal explosions and limit the risk of external ignition contributes to the smooth operation of activities within the hangar.

Oil and Gas Exploration Sites

In oil and gas exploration sites, where the extraction of hydrocarbons occurs, the motors operate essential equipment such as drilling rigs and pumps. These components are designed to work in environments with combustible gases.

Mines

Mines often contain explosive gas and dust atmospheres, posing particular dangers. Class I, Division 1 motors are used in various mining equipment, providing a dependable power source while reducing the fire risk. In addition, their sturdy construction and safety features help to improve the overall safety and efficiency of mining operations.

Available Brands and Services

At Dietz Electric Co., we provide solutions for supplying and servicing Class I, Division 1 motors, focusing on Groups C and D. All of our motors have been tested and designed to meet or exceed NEMA and NEC specifications. They are also CSA- and UL-approved for utilization in explosive and hazardous locations.

Some of the explosion-proof motors that we currently supply include the following:

- ABB XP100

- Brook Crompton NEMA Explosion-Proof Motors

- Hyundai Explosion Proof Motors

- Worldwide Electric Corp. Explosion-Proof Motors.

- TECO EXP NEMA Premium Efficiency Explosion-Proof Motors

- Tatung Explosion-Proof NEMA Premium Efficiency Series

- Baldor Explosion-Proof Motors

- Leeson Rigid Base Explosion-Proof Motors

Aside from our catalog of explosion-proof motors, we offer a specialized selection of custom electric motors. These are tailored for operation in Division 1, Class A or B hydrogen-rich, or equivalent hazardous environments. They are available in all NEMA frame sizes, ranging from ¼ to 100 horsepower, and provide flexibility with foot and flange mountings.

We also provide repair and maintenance services for explosion-proof and custom electric motors. These include explosion-proof Class I, Division 1 motors (Class C and D) and Division 1, Class 2, E, F, and G motors.

Our qualified technical staff has the necessary expertise in electrical and mechanical aspects to ensure that all repairs adhere to various requirements. Examples include NEMA and the Institute of Electrical and Electronic Engineers (IEEE) Standard 112A.

Available Motors

ABB XP100 - Class I, Group C & D, Class II, Groups F & G, Division 1 Premium Efficiency

Here are the available motors and some of their respective features:

Features

- 1 to 300 HP

- Service factor, 40oC ambient

- T3C temperature code

- 900, 1200, 1800, or 3600 RPM

- 3 phase, 60 Hz; 230/460-volt operation under 25 HP, 460 volt 25HP and above; 200 & 575 volts available

- Class F insulation, Class B temperature rise

Brook Crompton UL/CSA Approved Class I Group C & D Class II Groups E, F & G T3B 140 - 250T frame UL/CSA Approved Class I Group D Class II Groups E, F & G T3B 280T and above

Features

- NEMA MG1 Part 31 Inverter Duty

- UL-certified 5:1 constant torque

- CSA-certified 10:1 constant torque

- SF 1.15 sine Wave. 1.0 SF SF VFD

- IP55 degree of protection

- NEMA Design B performance

- Class F insulation

Hyundai Explosion Proof Motors - Rigid Base

Features

- 1 to 250 HP

- 3600, 1800, and 1200 RPM

- 208-230/460 volt (1-125 HP)

- 460 volt (150-250 HP)

- TEFC enclosure

- 15 service factor

- Class F insulation

Worldwide Explosion-Proof Motors, Premium Efficient Class I, Division 1, Groups C & D, T3C Temp Code Class II, Division 1, Groups E, F & G (254T-449T only)

Features

- 1 to 300 HP

- 3600, 1800, and 1200 RPM

- 208-230/460 volt (1-100 HP)

- 460 volt (125-300 HP)

- TEXP enclosure

- 15 service factor

- Class F insulation

TECO NEMA Premium Efficiency Explosion-Proof Totally Enclosed Fan Cooled 1 HP through 150 HP Speed 3600, 1800, 1200 RPM Voltage 230/460V (usable on 208V), 575V Frequency 60 Hz

Features

- Inverter duty magnet wire

- Rugged cast-iron construction

- Non-sparking external fan

- Non-sparking brass flingers on both ends

- Oversized cast-iron conduit box

- Non-hygroscopic insulation system

- Zn-Cd plated hardware

Leeson Motors

Features

- 33 to 350 HP

- 1200, 1800, & 3600RPM

- 56 – 449T Frames

- 1 Phase up to 5 HP

- 115/230V, 230/460V

- Nema Premium Efficient

- UL and CSA Certified

Trust Dietz Electric Co. for High-Quality Motors!

Dietz Electric Co. is a full-service electric motor control repair expert that serves various industries. We provide motor controllers at exceptionally affordable prices, including pilot devices, logic control, DC and AC contactors, pressure switches, and more! We also offer drives and power transmission products from major manufacturers.

Contact us for inquiries or request a quote to get started!