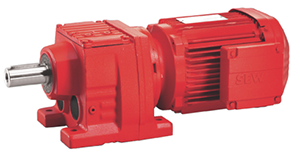

R-Series Parallel Gearmotors

SEW-Eurodrive’s R-Series parallel gearmotors deliver exceptional performance and reliability combined with low maintenance. Available in many confgurations, they continually distinguish themselves with their high effciency and durable gearing.

Product Range

- Power ratings from 0.05 to 433 HP

- Ratios from 1.3 to 23,401

- Output torques to 159,300 lb-in

Reducer

- Efficiency = 98.5% (1-stage) 97% (2-stage) or 95.5% (3-stage)

- Gears manufactured from certified steel, heat treated to a case hardness of 58-62 Rockwell C for infinite fatigue strength

- Finished ground or shaved gear teeth to assure minimum noise, minimum heat, and maximum mechanical efficiency

- Anti-friction bearings for optimum load capacity and long life

- Captured keys on input and output shafts

- R37-R167 gear housing contains high strength cast iron, SAE Class 30 or equivalent (GG20)

- R27 housing contains high strength pressure-cast aluminum

- O-ring on flange to prevent oil leakage when mounted on a surface that is not totally flat

- High cross-section modulus design, rugged monobloc design for maximum rigidity

- Center tapped holes on output shafts to aid the installation of shaft components

- Exclusive interlocking 2-piece seal design consisting of a patented bi-helix FKM inner seal and a double-lip Nitrile (Buna N) outer seal – provides three sealing surfaces against contaminants

- Metric or Inch dimension output shaft

- Removable inspection cover

- Shock capacity meets or exceeds AGMA 6009-A00

Motor

- Inverter duty

- Connection terminals

- Low rotor inertia for high cycling and tight control

- EISA (IE3) “Premium” available

- 50Hz, 60Hz, or 50/60Hz global motor for shipment into Europe

Mounting

- B5 flange with centering tenon

- B14 flange with centering tenon for sizes R07-R87

- Foot/Flange for sizes R07-R87

- Flange with extended bearing (RM) for mixer applications

- Can be ordered for any mounting orientation

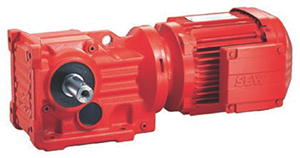

F-Series (the Snuggler®) - Parallel Helical Gearmotors

SEW-Eurodrive’s F-Series parallel helical gearmotor is the ideal drive for tight spaces. This compact drive, with its multiple mounting configurations and shaft designs, is a rugged alternative to right-angle gearmotors.

Product Range

- Power ratings from 0.05 to 336 HP

- Ratios from 3.77 to 29,211

- Output torques to 159,300 lb-in

Reducer

- Efficiency = 97% (2-stage) or 95.5% (3-stage)

- Gears manufactured from certified steel, heat treated to a case hardness of 58-62 Rockwell C for infinite fatigue strength

- Finished ground or shaved gear teeth to assure minimum noise, minimum heat, and maximum mechanical efficiency (approximately 1.5% loss/stage)

- Anti-friction bearings for optimum load capacity and long life

- Captured keys on input and output shafts

- F37-F157 gear housing contains high strength cast iron

- SAE Class 30 or equivalent (GG20)

- F27 housing contains high strength pressure-cast aluminum

- O-ring on flange to prevent oil leakage when mounted on a surface that is not totally flat

- High cross-section modulus design, rugged monobloc design for maximum rigidity

- Center tapped holes on output shafts to aid the installation of shaft components

- Exclusive interlocking 2-piece seal design consisting of a patented bi-helix FKM inner seal and a double-lip Nitrile (Buna N) outer seal – provides three sealing surfaces against contaminants

- Metric or Inch dimension output shafts

- Removable inspection cover

- Shock capacity meets or exceeds AGMA 6009-A00

Motor

- Inverter duty

- Connection terminals

- Low rotor inertia for high cycling and tight control

- EISA (IE3) “Premium” available

- 50Hz, 60Hz, or 50/60Hz global motor for shipment into Europe

Mounting

- Built-in torque arm for shaft mounting

- B14 or B5 flange with centering tenon

- Tapped rail holes for foot mounting

- Can be ordered for any mounting orientation

K-Series - Helical-Bevel Gearmotors

SEW-Eurodrive’s K-Series helical-bevel gearmotors contain high torque density with the highest efficiency available in a right-angle design. Instead of losing energy via the sliding friction of a worm gear, the K-series uses much lower rolling friction of helical and bevel gears. The result is minimum heat and maximum energy savings to the end user.

Product Range

- Power ratings from 0.05 to 615 HP

- Ratios from 3.98 to 24,353

- Output torques to 442,500 lb-in.

Reducer

- Efficiency = 95.5%

- Gears manufactured from certified steel, heat treated to a case hardness of 58-62 Rockwell C for infinite fatigue strength

- Finished ground or shaved gear teeth to assure minimum noise, minimum heat, and maximum mechanical efficiency

- Anti-friction bearings for optimum load capacity and long life

- Captured keys on input and output shafts

- Gear housing contains high strength cast iron, SAE Class 30 or equivalent (GG20)

- O-ring on flange to prevent oil leakage when mounted on a surface that is not totally flat

- High cross-section modulus design, rugged monobloc design for maximum rigidity

- Center tapped holes on output shafts to aid the installation of shaft components

- Exclusive interlocking 2-piece seal design consisting of a patented bi-helix FKM inner seal and a double-lip Nitrile (Buna N) outer seal – provides three sealing surfaces against contaminants

- Metric or Inch dimension output shafts

- Removable inspection cover

- Shock capacity meets or exceeds AGMA 6009-A00

Motor

- Inverter duty

- Connection terminals

- Low rotor inertia for high cycling and tight control

- EISA (IE3) “Premium” available

- 50Hz, 60Hz, or 50/60Hz global motor for shipment into Europe

Mounting

- Torque arm for shaft mounting

- B14 or B5 flange with centering tenon

- Tapped rail holes for foot mounting

- Can be ordered for any mounting orientation

S-Series - Helical-Worm Gearmotors

SEW-Eurodrive’s S-Series right angle gearmotors offer helical-worm gearing that combines durability with exceptional performance in a compact design. Its helical input stage provides greater efficiency than a single stage worm unit. An additional helical gear unit added to the input enables very large ratios.

Product Range

- Power ratings from 0.05 to 46 HP

- Ratios from 3.97 to 33,818

- Output torques to 35,400 lb-in

Reducer

- Efficiency up to 94%, depending on ratio

- Worm shaft and helical gears manufactured from certified steel, heat treated to a case hardness of 58-62 Rockwell C for infinite fatigue strength

- Gears are milled, hardened and ground to assure minimum noise, minimum heat, and maximum efficiency

- Torque rating based upon mechanical capacity under continuous duty operation

- Gearcases made of high strength gray cast iron, SAE Class 30 or equivalent (GG20)

- Anti-friction bearings for optimum load capacity and long life

- Captured keys on input and output shafts

- O-ring on flange to prevent oil leakage when mounted on a surface that is not totally flat

- High cross-section modulus design, rugged monobloc design for maximum rigidity

- Center tapped holes on output shafts to aid the installation of shaft components

- Exclusive interlocking 2-piece seal design consisting of a patented bi-helix FKM inner seal and a double-lip Nitrile (Buna N) outer seal – provides three sealing surfaces against contaminants

- Metric or Inch dimension output shaft

- Removable inspection cover

- Shock capacity meets or exceeds AGMA 6009-A00

Motor

- Inverter duty

- Connection terminals

- Low rotor inertia for high cycling and tight control

- EISA (IE3) “Premium” available

- 50Hz, 60Hz, or 50/60Hz global motor for shipment into Europe

Mounting

- Torque arm for shaft mounting

- B14 or B5 flange with centering tenon

- Foot mounting

- Can be ordered for any mounting orientation

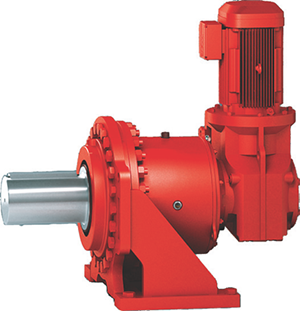

P2 series - Industrial Planetary Gearmotors / Gear Units

SEW-Eurodrive’s P2 series combination planetary gearmotor offers high torque with low output speed. The planetary half provides high output torque in a compact design. The gearmotor half provides additional ratio and integrates directly onto the input to eliminate a coupling and an adapter flange. The result is a very rigid, compact gear unit. To enhance design flexibility, the gearmotor input is available in either coaxial inline or right-angle.

Product Range

- Helical and bevel-helical

- Ratios from 100:1 to more than 5,000:1

- Torque capacities from 212,000 – 4,425,000 lb-in.

Standard Features

- Case hardened, spur steel gears finished to AGMA 12 (ISO 6, DIN 6)

- High capacity anti-friction bearings – for extended life and trouble-free service

- Gray cast iron housings

- Splash and pressure lubrication

- Modular construction

- Compact design

- NEMA C-face adapter or V-belt motor mounting

- Stocked in USA – short delivery times

- International product support available through worldwide technical sales offices

- Manufactured in plants certified ISO 9001: 2000

Mounting Configurations

- Foot or flange mounted

- Horizontal or vertical mounting

- Solid shaft or shrink disc

Optional Features

- Torque arm

- Backstops

- Base plates

- Coupling guards

- Complete power transmission packages are available to include motor, AC drive, reducer, base plate, swingbase, coupling, and torque arm

- Standard gear unit can be easily adapted to include modifications that are specific to the application

- Multiple seal arrangements

Applications

- Low speed, high torque

- Drying processes – construction materials industry

- Filling processes – cement industry

- Slow running material processing – mixers, rotary filters

- Food industry

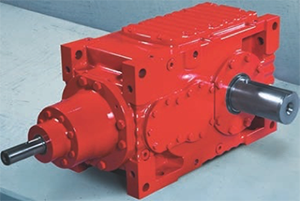

MC series – Compact - Heavy Industrial Speed Reducers

Thousands of MC series gear units have been successfully used in numerous applications throughout the world. MC series is designed for the smaller torque range up to 575,000 lb-in. Very compact. Global presence plus local support and assembly in USA!

Product Range

- Helical (parallel offset) and bevel-helical (right angle)

- Ratios from 7:1 to 112:1. Higher ratios with additional gear unit on input

- Output torque: 50,000 – 575,000 lb-in.

Standard Features

- 8 sizes available – avoids unnecessary oversizing

- Case hardened, helical and bevel steel gears finished to AGMA 12 (ISO 6, DIN 6)

- High capacity anti-friction bearings for trouble-free service and extended life

- Motor adapter (IEC or NEMA C-face) or V-belt + footed motor

- Gray cast iron housings

- Robust single block housing

- Modular construction

- Splash and pressure lubrication

- Short delivery – parts in stock for standard units

- Worldwide service, technical sales, and support

- Manufacturing plants certified ISO 9001: 2000

Mounting Configurations

- Foot or flange mounted

- Horizontal, vertical or upright

- Solid shaft, keyed hollow shaft, or shrink disc

- Flange or torque arm

Mixer and Agitator Drive - MC with Extended Bearing Distance (EBD)

In mixing and aerating applications, the impeller shaft is subject to large thrust and radial forces. Traditional mixer designs typically incorporate a radial bearing near or at the bottom of the impeller shaft and a thrust bearing at the top of the shaft. An alternate design uses an oversized gear unit. Either design is usually expensive.

SEW-Eurodrive’s Extended Bearing Distance (EBD) design offers a stronger bearing within the gear unit itself. Therefore, it is often unnecessary to oversize the gear unit.

Two solid shafts are available. For equipment containing an external radial bearing, the smaller diameter shaft can support large axial and moderate radial loads. For equipment with no external bearings, the larger diameter can support high radial and moderate axial loads. An alternative hollow shaft is available for moderate radial and moderate axial loads.

Product Range

- Output torque capacity to 570,000 lb-in

- Input HP capacity to 1400 HP

- Ratios from 7:1 to 112:1 with single unit

- Ratios > 112:1 with compound units

- Double and triple reductions within single unit

Standard Features

- Efficient helical and bevel-helical gearing

- Hollow or solid output shaft

- Spherical bearing with paired taper roller bearings

- Radial labyrinth sealing system

- Case hardened, helical steel gears finished to AGMA 12 (ISO 6, DIN6)

- Gray cast iron housing

- Splash and pressure lubricated

- Modular construction – fast delivery and global availability

- Quick shipments from stock in Lyman, SC

- Global product support through international sales offices

Mounting Configurations

- Parallel-offset or right-angle configuration

- Foot mounting or flange mounting (B14 or B5)

- B14 flange (EZ design) enables the use of a custom mounting flange for new or retrofit installations

- Horizontal or vertical shaft

- Solid shaft or keyed hollow shaft

- C-Face or V-belt arrangement for motor input

DR Motor - Modular AC Motors and Brakemotors

The low-inertia rotor design of SEW’s squirrel-cage DR motor and brakemotor provides outstanding system stability, tight control, and high-cycling capacity. In many cases, its high performance allows it to replace a servo motor.

With a patented dual coil design and specialized rectifiers, its fail-safe brake delivers extremely fast stopping and starting times with minimal drift. Moreover, its low-noise operation and quiet braking make it perfectly suited for theater applications.

Every DR motor frame is available with multiple brake sizes to optimize cost. Select higher torque for a stopping brake or lower torque for a VFD holding brake. Its various connector options make the DR motor especially suitable for automotive manufacturers.

Standard Features

- 0.25 to 300 HP

- Inverter duty; meets or exceeds NEMA MG1, part 30/31

- Speed range: 10-60Hz (6:1), constant torque with standard cooling fan, 1.0 SF, 4-pole, 40°C max

- Continuous duty, TEFC

- 1.15 Service Factor @ constant speed

- Low rotor inertia – high cycling, tight control

- IE1 (<1.0 HP), IE2 (High), or IE3 (Premium) efficiency

- Connection terminals

- Double sealed or shielded bearings lubed for life

- Stainless steel nameplate

- UR, NEMA Premium verified, CSA Energy Efficient verified, CE

Mounting Styles

- Integral – for SEW gear units

- IEC flange

- IEC foot mount

- NEMA C-Face flange (size 56C – 184TC) – 4 pole

Insulation System

- Phase insulators – prevents phase-to-phase shorts

- Class H varnish; dipped, baked, and cured

- Slot liners – prevents winding-to-ground shorts

- Wire sleeves

- Voltage spike resistant per NEMA MG1-31.4.4.2, which states 1600 V peak at .1μs or larger rise time

SEW Eurodrive Power Transmissions

SEW Eurodrive Power Transmissions