Have an application for high-performance NEMA motors? Look no further than Dietz Electric. As a leading distributor of ABB motors, we offer a comprehensive selection of reliable and efficient NEMA solutions to meet your industrial needs. From general purpose to rugged explosion-proof motors, Dietz Electric and ABB have you covered.

ABB GP 100A

GP100A is a new line of ABB NEMA aluminum housing motors, suitable for general purpose use. They weigh less than comparable rolled-steel frame motor designs, yet provide more structural strength for a wide variety of industrial applications. Available in foot mounted and C-face footless design. These motors are designed to NEMA Premium efficiency and are designed to be run DOL (Direct on line) or with variable speed operations.

Features

Features

- 1–20 Hp (0.75–15 kW)

- NEMA frame 143–256

- 230/460 and 575 volts

- 2, 4, 6 pole

- Aluminum frame and end-shields

- Aluminum diagonally split oversized terminal box

- Zinc-plated hardware

- Epoxy paint for corrosion resistance

- Class F insulation at 1.15SF, NEMA Class B temperature rise at 1.0SF

- Inverter duty per NEMA MG1 Part 31 (VT 20:1, CT 4:1)

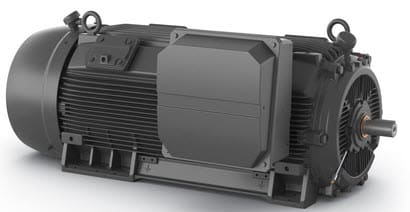

ABB GP100

GP100 is a new line of ABB NEMA cast-iron motors that utilize the same design philosophy that goes into the design of our renowned severe duty line of motors… ruggedness, reliability, performance and efficiency. The design provides high structural strength through the use of finite element analysis to strategically place material within each component to resist the effects of stress and vibration. Materials for resistance to corrosion are liberally used throughout for long life in a wide variety of industrial applications.

Features

Features

- 1–200 Hp (0.75–150 kW)

- NEMA frame 143–449

- 230/460, 460 and 575 volts

- 2, 4, 6, 8 pole

- IP54 (280-449 frame) and IP55

- Bearings in 143T–256T frames are lubricated for life

- Durable cast iron frame design

- Terminal box: Aluminum frame (140-250 frame) | Stamped steel (280-400 frame) | Cast iron (440 frame)

- Zinc-plated hardware

- Epoxy paint for corrosion resistance

- Class F insulation, NEMA Class B temperature rise

- Inverter duty per NEMA MG1 Part 31 (VT 20:1, CT 4:1)

ABB SD100

A new line of ABB NEMA cast-iron motors, used in severe duty applications are designed and built for long, trouble-free life in harsh environments. Industries in chemical processing, mining, foundry, pulp and paper, waste management, and more trust their operation to SD100. They are available with a wide selection of application-matched modifications to meet specific needs, ambient conditions and installation requirements. These industrial workhorses are rugged and efficient, ensuring performance in the most severe operating environments.

Features

- 1–400 Hp (0.75–298 kW)

- NEMA frame 143–S449SS

- 230/460, 460 and 575 volts

- 2, 4, 6, 8 pole

- IP55

- Durable cast iron frame design

- Class I, Division 2 standard

- Class II, Division 2 standard on 280-400 frame (optional on others)

- Cast iron diagonally split oversized terminal box

- Zinc-plated hardware

- Epoxy paint for corrosion resistance

- Stainless steel nameplate for durability

- Class F insulation, NEMA Class B temperature rise

- Inverter duty per NEMA MG1 Part 31(VT 20:1, CT 20:1 on 140-360 frame, 4:1on other frame sizes)

ABB SD100 IEEE841

The SD100 IEEE841 motor is the ultimate NEMA design motor that meet or exceed IEEE Standard 841 requirements for efficiency, performance, construction, adjustable-speed operation and long service life in the most demanding applications.

Features

Features

- 1–400 Hp (0.75–298 kW)

- NEMA frame 143–S449

- 208-230/460, 230/460, 460 and 575 volts

- 2, 4, 6, 8 pole

- IP55 (optional up to IP66)

- Inpro/Seal® bearing isolators are included on both ends

- Bearings have automatic grease relief fitting to prevent over-greasing

- Available with C-face or D-flange mounting construction

- Durable cast iron frame design

- Class I, Division 2 standard

- Class II, Division 2 standard

- Cast iron diagonally split oversized terminal box

- Stainless steel embossed nameplate

- Epoxy paint for corrosion resistance

- Class F insulation, NEMA Class B temperature rise

- Low vibration 0.06 IPS

- Inverter duty per NEMA MG1 Part 31 (VT 20:1, CT 20:1 on 140-360 frame 2,4,6 pole; CT 4:1 on others)

- 5 year warranty

ABB SD661

The SD661 motor is built in compliance with the requirements of API661 standard, by incorporating regreaseable roller bearings and cast-iron end cap son frames 210-360. These motors are used for heavy belt-driven air cooled heat exchangers in the petrochemical, energy and other similar industries.

Features

Features

- 1–75 Hp (0.75–56 kW)

- NEMA frame 184-365

- 460 and 575 volts

- 4 and 6 pole

- IP56

- Inpro/Seal® bearing isolators are included on both ends

- Bearings have automatic grease relief fitting to prevent over-greasing

- Class I, Division 2 standard

- Class II, Division 2 standard

- C4 painting system

- Durable cast iron frame design

- Cast iron diagonally split oversized terminal box

- Epoxy paint for corrosion resistance

- Stainless steel nameplate for durability

- Class F insulation, NEMA Class B temperature rise

- Low vibration 0.06 IPS

- Inverter duty per NEMA MG1 Part 31 (VT 20:1, CT 20:1 on 140-360 frame 4 & 6 pole, CT 4:1 on others)

- 5 year warranty

ABB SD200

SD200 is a new line of ABB NEMA motors: flexible severe duty motor designed for long, trouble-free life in harsh environments. SD200 is the next generation of severe duty motors, not only meeting but exceeding NEMA Premium and U.S. DOE requirements.

Features

Features

- 125–800 Hp (93-597 kW)

- NEMA frame 444-5013

- 460 and 575 volts

- 2, 4, 6, 8 pole

- IP55

- C-face and D-flange options

- Class I, Division 2 standard

- Class II, Division 2 standard

- Durable cast iron frame design

- Cast iron, field-modifiable location (F1/F2) and rotation

- Zinc-plated hardware

- Epoxy paint for corrosion resistance

- Stainless steel nameplate for durability

- Class H insulation, NEMA Class B temperature rise

- Inverter duty per NEMA MG1 Part 31 (VT 20:1, CT 4:1)

ABB SD200 IEEE841

The SD200 841 motor is a new generation of NEMA design motor that meet or exceed IEEE Standard 841-2021 requirements for efficiency, performance, construction, adjustable-speed operation and long service life in the most demanding applications.

Features

Features

- 125–400 Hp (93–298 kW)

- NEMA frame 444–L449

- 460 and 575 volts

- 2, 4, 6, 8 pole

- IP56

- Inpro/Seal® bearing isolators are included on both ends

- Bearings have automatic grease relief fitting to prevent over-greasing

- Available with C-face or D-flange mounting construction

- Durable cast iron frame design

- Class I, Division 2 standard

- Class II, Division 2 standard

- Cast iron diagonally split oversized terminal box

- Stainless steel embossed nameplate

- Epoxy paint for corrosion resistance

- Class H insulation, NEMA Class B temperature rise

- Low vibration 0.06 IPS

- Inverter duty per NEMA MG1 Part 31 (VT 20:1, CT 4:1)

- 5 year warranty

ABB XP100

The XP100 motors is a new line of ABB NEMA motors – rugged explosion proof motors that provide reliable operation even under extreme conditions. They are UL® listed and CSA certified for gas and dust ignition environments and suitable for Class I, Groups C&D and Class II Groups F&G, Division 1 hazardous area classification. The XP100 ID1 drill rig duty motors is certified for Class I, Group D, Division 1 hazardous locations.

Features

Features

- 1–300 Hp (0.75–223 kW)

- NEMA frame 140-440

- Horizontal footed and footless, Vertical C-Face mounting

- 208-230/460V, 230/460V, 460V, and 575V

- 2, 4, 6, 8 pole

- IP65

- Bearings are double-shielded: Regreaseable inlet & outlet

- Durable cast iron frame design

- Stainless steel nameplate

- Epoxy paint for corrosion resistance

- Class F insulation, NEMA Class B temperature rise, T3C

- Inverter duty per NEMA MG1 Part 31 (VT 20:1, CT 4:1)

ABB SD10 Multi Speed

ABB SD10 MS high efficiency, severe duty, multi-speed motors are ideal for both indoor and outdoor applications and in severe duty operating atmospheres, such as cooling towers, which require more than one base speed. They meet or exceed NEMA and CSA standards and the operational standards for severe operating environments.

Features

- 1 to 400 HP

- 1.15 service factor, 40°C ambient

- 1 winding, 1800/900 RPM, variable torque

- 3-phase, 60 Hz; 460 V; 200, 230 & 575 V available

- Meets or exceeds EPAct efficiency standards

- Class F insulation, Class B temperature rise @ 1.0SF

- NEMA design B (except as noted), continuous duty

- 143T to S449T

ABB LP100 HP100 Vertical Pump Motors

ABB’s new line of Vertical Solid Shaft pump motors are designed and built to operate under harsh environments. LP100 are inline high thrust and extra high thrust motors, while HP100 are P-base normal thrust motors. These motors are designed to meet or exceed the NEMA Premium® efficiency as well as the most stringent industry standards API610 (LP100) and IEEE 841. A wide selection of options, among them bearing isolators and ceramic bearings on drive end, extra high thrust and non-reverse ratchet for LP100 motors make these motors suitable for almost any requirement.

Features

Features

- 3–250 Hp (2.2–186 kW)

- NEMA frame 180-440

- 230/460, 460 and 575 volts

- 2, 4, 6 pole

- IP55 (IP56 optionally)

- HP100 standard thrust; LP100 high or extra high trust

- IEEE841 – 2021 and API610 (as option)

- Cast iron oversized conduit box

- Zinc-plated hardware

- Bolted lifting eye

- Epoxy paint for corrosion resistance

- Stainless steel nameplate for durability

- Class F insulation at 1.15SF, NEMA Class B temperature rise at 1.0SF

- Inverter duty per NEMA MG1 Part 31 (VT 20:1. CT 4:1)

- 3 year warranty

ABB DP200 HPS (Horizontal Pump Systems)

ABB DP200 is a New Generation of ABB NEMA Pump motors: Based on the flexible severe duty motor designed of SD200 it emulates its long, trouble-free life in harsh environments as well as its flexible configuration. DP200 is the next generation of pump motors for the horizontal pump systems.

Features

Features

- 450–800 Hp (93–597 kW)

- NEMA frames 5011–5013

- 460, 575 Volts

- 2 pole design

- IP55

- Class I Division 2, Groups A, B, C, D – T2D

- Class I Zone 2 Group IIA, IIB , IIC T2D

- Stator RTDs (resistant temperature detectors)

- Provisions for: Bearing RTDs | Vibration sensors

- Flexible oversized terminal box that is field modifiable (F1/F2)

- High strength zinc-plated hardware

- Durable cast iron frame design

- Insulated bearing on the NDE (non-drive-end)

- Class H insulation with NEMA Class B temperature rise for extra margin of thermal life

- Inverter duty per NEMA MG1 Part 31(VT 20:1, CT 4:1 [2:1 for 700-800Hp])

- Meets or exceeds standards API610 and IEEE841

- 3-year warranty

Low Voltage Flameproof Motors

ABB offers full range of IECEx/ATEX certified low voltage flameproof IE2 motors, according to IEC 60034-30, 2008.

Features

Features

- Ex d / Ex de protection

- 0.55 to 950 kW output power

- IEC 80 to 450 frame size

- 2 to 8 poles

- All commonly used voltages

- 50 or 60 Hz frequency

- IP 55 protection type for zone 1 or 2

T1 – T4 temperature classes - IECEx / ATEX certified, Equipment protection levels (EPLs), GOST (Russia), CQST (China), Inmetro (Brazil)

- VSD applicable as standard

- Variants for different standards in the oil and gas sector, such as Norsok and Shell

- VIK = Marine use and open deck with most classification societies

High Voltage Flameproof Motors

Flameproof motors certified according to EN standards, fulfilling ATEX Directive 95/9/EC, CSA-UL, GOST (Russian) – Motors are designed to withstand without any damage the pressure caused by an internal explosion and are also able to prevent flame propagation outside. Offers the advantages of no purging before starting, no pressurization system required, no inert gas needed, no thermal limitation for “te” time, and no need for system test in VSD applications. Individual certification not required for these motors and they have low maintenance costs.

Features

Features

- Totally enclosed, fan cooled high voltage motors, type of protection Ex d IIB/IIC, Ex de IIB/IIC

- 160 to 8000 kW output power

- IEC 355 to 900 frame size

- 2 to 18 poles

- LV – 11 kV voltages

- 50 or 60 Hz frequency

- Environment IP 55 as standard (higher on request)

- Zone 1 or 2 protection

- T4 temperature class

- Horizontal or Vertical mounting

- IC411 or IC511 cooling

- Antifriction or sleeve bearings

- Direct-on-line or variable speed drive supply

- Standards EN, IEC, BS, ANSI, NEMA, IEEE, VDE, CSA, UL, GOST

ABB Motors

ABB Motors