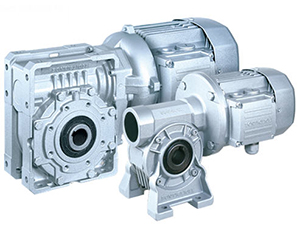

VF/W - Universal worm gear motor

Bonfiglioli worm gear motor is a milestone for the industry worldwide. They succeeded in combining uncompromising quality with state-of-the-art technology and renown price effectiveness.

Absolute flexibility is given by the wide choice of several mounting options, shaft configurations and motor interface, all offered as standard. The helical-worm and the double-worm version, with or without the torque limiter, also add up, creating a highly versatile drive system.

Torque Range

13 Nm… 7.100 Nm

Mechanical Rating (n1= 1400 min^-1)

0,04 … 75 kW

Gear ratios

7 … 10000

Output Configurations

Keyed Hollow Shaft

Plug-in Solid Output Shaft

Torque Limiter as an Option

Input Configurations

VF and W: IEC-normalized motor adapter

VF and W: solid input shaft

Applicable AC motors

VF and W: IEC-normalized motors and brake motors – BN series/BE series

W: integral motors and brake motors series M/ME series

Single and dual speed motors

Main Brake Features

DC and AC supply

Faster Brake Engage/Disengage through Electonically

Controlled AC/DC Rectifier type SB, NBR, SBR (options)

Main Motor Options

Thermistors and Thermostates sensor

Separate Supply Forced Ventilation

Line Driver and Push-Pull Incremental Encoder

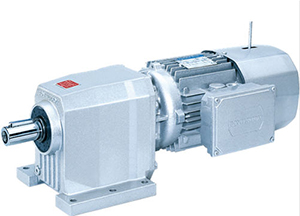

Helical gearmotors and gearboxes, C Series

Top torque density, product variety, extremely wide speed choice, great compactness and price effectiveness make the C series the unparalleled line of helical gear motors and speed reducers.

Torque Range

45 Nm… 12.000 Nm

Mechanical Rating (n1= 1400 min^-1)

0,08 kW … 213 kW

Gear ratios

2,6 … 1481

Output Configurations

Foot and Flange mount

Metric or Inch series Solid Output shaft

Input Configurations

IEC and NEMA motor Adaptors

Metric or Inch series Solid Output shaft

Applicable AC motors

Integral motors and Brake motors – M series/ME series

IEC-normalized Motors and Brake motors – BN series/BE series

Single and Dual Speed Motors

Main Brake Features

DC and AC supply

Faster Brake Engage/Disengage through Electonically

Controlled AC/DC Rectifier type SB, NBR, SBR (options)

Main Motor Options

Thermistors and Thermostates sensor

Separate Supply Forced Ventilation

Line Driver and Push-Pull Incremental Encoder

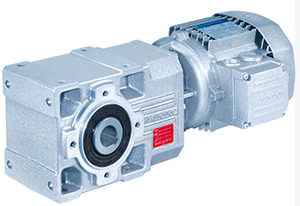

Bevel helical gearmotors and gearboxes, A Series

The A Helical bevel gear motor series is the first product to prove equally good in regard to efficiency and versatility within a highly competitive context, both performance- and price-wise.

Torque Range

100 Nm… 14.000 Nm

Mechanical Rating (n1= 1400 min^-1)

0,22 … 150 kW

Gear ratios

5,4 … 1715

Output Configuration

Foot and Shaft mount – Two Bore Options per Size

Keyless Shrink Disc Fitting

Metric or Inch series Solid Output shaft

Adapter bushings matching more shaft diameters

Splined hollow shaft to DIN 5480

Input Configurations

IEC and NEMA motor Adaptors

Servomotor adapters

Metric or Inch series Solid Input Shaft

Applicable AC motors

Integral motors and Brake motors – M series/ME series

IEC-normalized Motors and Brake motors – BN series/BE series Single and Dual Speed Motors

Main Brake Features

DC and AC supply

Faster Brake Engage/Disengage through electronically

Controlled AC/DC Rectifier type SB, NBR, SBR (options)

Main Motor Options

Thermistors and Thermostates sensor

Separate Supply Forced Ventilation

Line Driver and Push-Pull Incremental Encoder

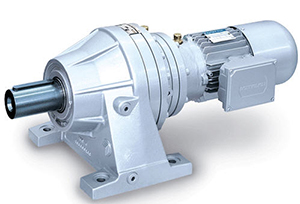

300 Series - Planetary gear motor

Compact, and yet extremely powerful, are the units of the 300 Planetary gear motor series. Their planetary drive train makes them the ideal choice for all the severe duty applications where shock loadings and impacts are more the rule than the exception. The product configuration is highly versatile, due to several options as far as the mounting, the gear layout, the output shaft and the motor interface. All the features are available for each of the 18 finely spaced frame sizes, spanning over the 1.000 – 1.400.000 Nm torque range. Finding the perfect match to any drive problem is therefore more than a wish, it is something users can safely rely on – always.

Torque range

1000 … 1287000 Nm

Mechanical rating (n1 = 1500 min^-1)

up to 450 kW

Gear ratios

3.4 … 5234

Gear unit versions

In line

Right angle (with Gleason bevel gear set)

Output

Foot and flange mounted

Output shaft: keyed solid, splined, splined hollow, hollow shaft with shrink disc

Input

IEC and NEMA motor adaptors

Solid input shaft with or without fan cooling – inch or metric dims.

Applicable AC motors

Integral motors and brake motors – M series / ME series

IEC-normalized motors and brake motors – BN series / BE series

Single and dual speed motors

Main brake features

DC and AC supply

Faster brake reaction through electronically controlled rectifier

Main motor options

Thermistors and thermostat sensors

Independent forced cooling

Line driver and push-pull incremental encoder

Bonfiglioli Power Transmission

Bonfiglioli Power Transmission